Opportunities in sisal value chain in Tanzania

The Sisal Board of Tanzania (SBT) reports that over 100,000 hectares of land across various regions are available for sisal cultivation, suitable for both large-scale plantations and smallholder farming

Tanzania is one of the world’s leading sisal producers, a position strengthened by rising global demand for eco-friendly, sustainable materials. This demand presents vast opportunities across the sisal value chain—from cultivation to processing and manufacturing. The following are key areas within Tanzania’s sisal sector with significant potential for investment and development.

1. Cultivation

Global demand for sisal continues to grow, driven by its natural fiber applications in textiles, construction materials, and biodegradable packaging. This surge in demand opens up opportunities for sisal cultivation across Tanzania, which is already a top producer.

The Sisal Board of Tanzania (SBT) reports that over 100,000 hectares of land across various regions are available for sisal cultivation, suitable for both large-scale plantations and smallholder farming. Expanding sisal farming could bring economic benefits to local communities, as sisal is a hardy, drought-resistant crop that thrives in semi-arid regions where other crops may struggle. With investments in modern agronomic practices, farmers can improve yields, support rural employment, and meet growing global demand.

Key Facts:

- Sisal reaches harvest maturity in approximately 3 years.

- One hectare of sisal yields between 1 and 3 tons of sisal leaves.

- Initial cultivation costs for one hectare (including land preparation, plowing, planting, and field maintenance) range from TZS 3 to 3.5 million over the first 3 years, with costs decreasing in subsequent years.

- Harvesting and processing leaves cost between TZS 1.2 and 1.7 million per hectare.

- The local selling price of one ton of sisal fiber is TZS 3.5 million, or USD 1,700 for export (FOB).

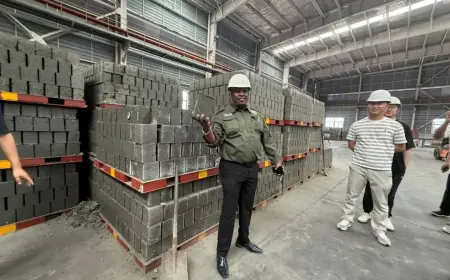

2. Processing Centers

Despite increased sisal cultivation, Tanzania faces a shortage of processing centers, which limits the sector’s growth potential. Sisal fiber extraction involves decortication, brushing, baling, and packaging, but the limited number of processing centers—and their distance from many farms—increases logistical costs and reduces supply chain efficiency.

Establishing additional processing centers near farming communities would greatly enhance efficiency. Although Tanzania produces small-scale decorticators, the quality of these machines and the fibers they produce could be improved, and high-quality machines can be costly. For instance, decorticators range from TZS 200 million to TZS 1 billion depending on capacity, while brushing machines cost between TZS 17 million and TZS 30 million, and baling machines range from TZS 3 million to TZS 78 million.

This situation presents opportunities for local manufacturers to produce affordable, high-quality machines for both smallholder and large-scale producers. Additionally, importing advanced equipment could further enhance fiber quality, boosting Tanzania's global competitiveness in sisal.

3. Bag Manufacturing

A primary use for sisal fiber is in bag manufacturing, particularly for agricultural packaging for crops like coffee, maize, and beans. Currently, only two companies in Tanzania—MeTL Group and Sisalana Cordana—produce sisal bags.

MeTL Group, which acquired Tanzania Portland Manufacturing (TPM) Ltd in 1998, operates sisal bag factories in Morogoro and Kilimanjaro, producing around 10 million bags annually. Sisalana Cordana, meanwhile, manufactures bags using machines originally designed for sisal carpets.

As global regulations shift toward eco-friendly packaging solutions, there is ample room for additional manufacturers to enter the sisal bag market. Scaling up production and modernizing facilities could position Tanzania as a major supplier of biodegradable packaging materials.

4. Eco-Manufacturing

Beyond bags, sisal offers potential in the eco-friendly manufacturing of products like gypsum boards, composite materials, and construction beams. These materials, made from sisal fibers, provide sustainable alternatives to conventional building supplies and align with global trends favoring green building practices.

Investing in eco-manufacturing can help Tanzania supply high-demand markets while promoting sustainable practices in the construction industry.

5. Animal Feed

Sisal waste, known locally as "mabaki ya mkonge," often goes unused despite its potential as animal feed. Innovative methods, such as using black soldier flies to process the waste into protein-rich feed for livestock, poultry, and fish, provide a profitable way to repurpose this byproduct.

With the growing livestock and aquaculture sectors in Tanzania, the demand for sustainable animal feed is increasing, making this a promising opportunity.

6. Additional Opportunities

Sisal offers further possibilities beyond fiber and animal feed production. Sisal insulin, extracted from the plant, can be used to produce sisal honey or sisal sugar, popular among people with diabetes for their low glycemic index. Additionally, sisal leaves can be processed into Agave jam, a natural sweet spread, or even Agave spirits, an alcoholic beverage similar to tequila, appealing to both domestic and international markets.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0